energy saving lubrication and cleaning technology

400-690-9091

◆Double pump design (built-in/external) Danish Grundfos G20 water pump,

Fully guarantee the heating water flow.

◆Proportional valve controls gas combustion to give full play to heat exchanger efficiency

◆Microcomputer detection and machine maple protection dual configuration, "double insurance" under any conditions of use

◆Automatically detect the running status and automatically display the fault

The DEPA-MD3 plastic molding release agent product line provides fast, efficient and non-polluting release. In addition, this product has been specially developed for products that require additional processes.

DEPA-MD2 Die Casting Release Agent Series Mainly for the die-cutting design of zinc, aluminum, magnesium and other alloy die-casting. The selection and dilution ratio of the products are determined according to the site process requirements.

DEPA-MD1 Die Casting Punch Lubricant Series is a high temperature, high pressure oily punch lubricant. It contains a special polarizing agent and a thixotropic agent to prevent dripping. At the same time, it is combined with high temperature and high pressure resistant additives and emulsifiers to form a tough lubricating film on the punching surface of the die casting machine.

The DEPA-DC water-soluble stretch oil series can be used directly or diluted with water depending on the load.The product has excellent lubricating properties and rust resistance, and the processed workpiece can be directly washed with water.

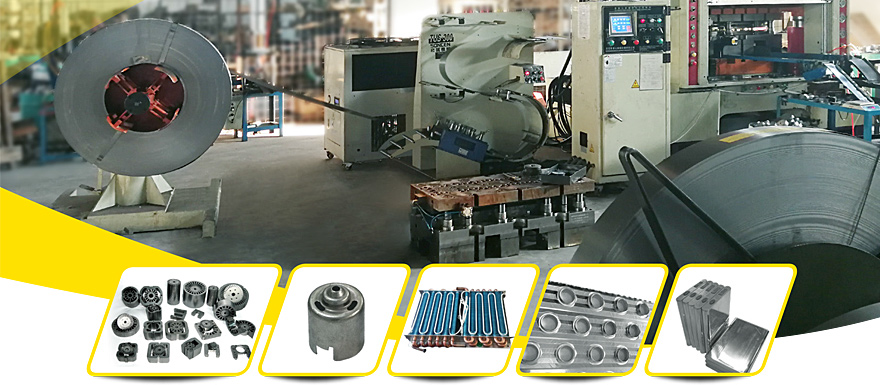

Designed for stretching, punching and cold forging of metal materials, the DEPA-DB series covers a wide range of processes and materials from lightweight deformation processing of zinc sheets to extremely cold-loaded alloy steel primary forming cold forging. . The extreme pressure lubrication properties of this series of products effectively reduce the strain and burr of processed products, extend the life of the mold and improve work efficiency.

DEPA-V Volatile High Speed Punching Oil Series is a high-speed blanking and shearing lubrication coolant for black and non-ferrous metals. It uses a highly refined desulfurized volatile solvent as a base oil with specially designed additive combinations. Excellent cooling, lubrication, anti-wear and anti-rust ability. This series of oils is suitable for high-speed punching and cutting of various metal foils. Mild odour, fast drying speed and good rust protection; can extend the life of the mold, no need to clean after processing. Widely used in motor rotor, housing, air conditioning fins and lithium battery shell molding lubrication.

The DEPA-V(W) series meets the high-end colorless, odorless and high flash point requirements.